About Mountain Bike Bump Stops

The one aspect of a mountain bike shock that is often overlooked is the bump stop. In a lot of cases, some manufacturers use an O-ring in place of a traditional bump stop. The main reason to have a bump stop is that along with shock damping, they help to control and absorb the ending stroke of the shock.

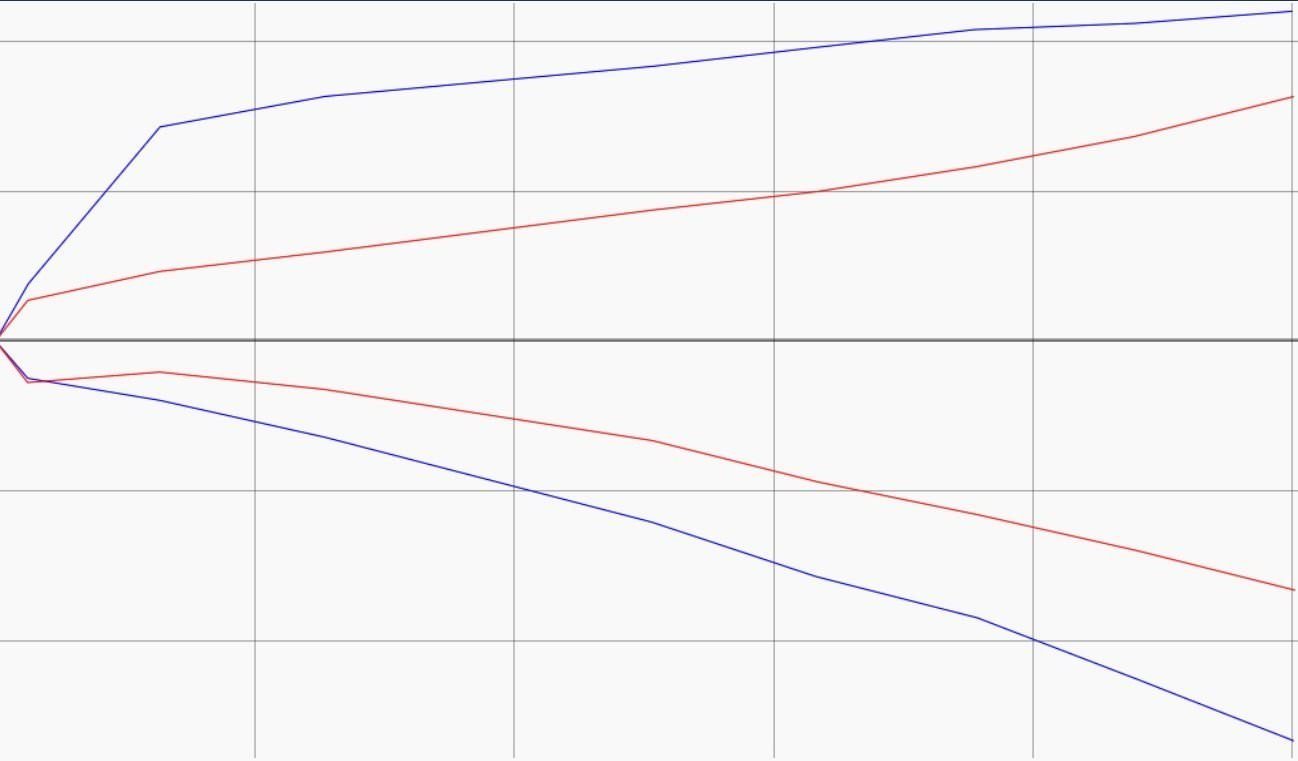

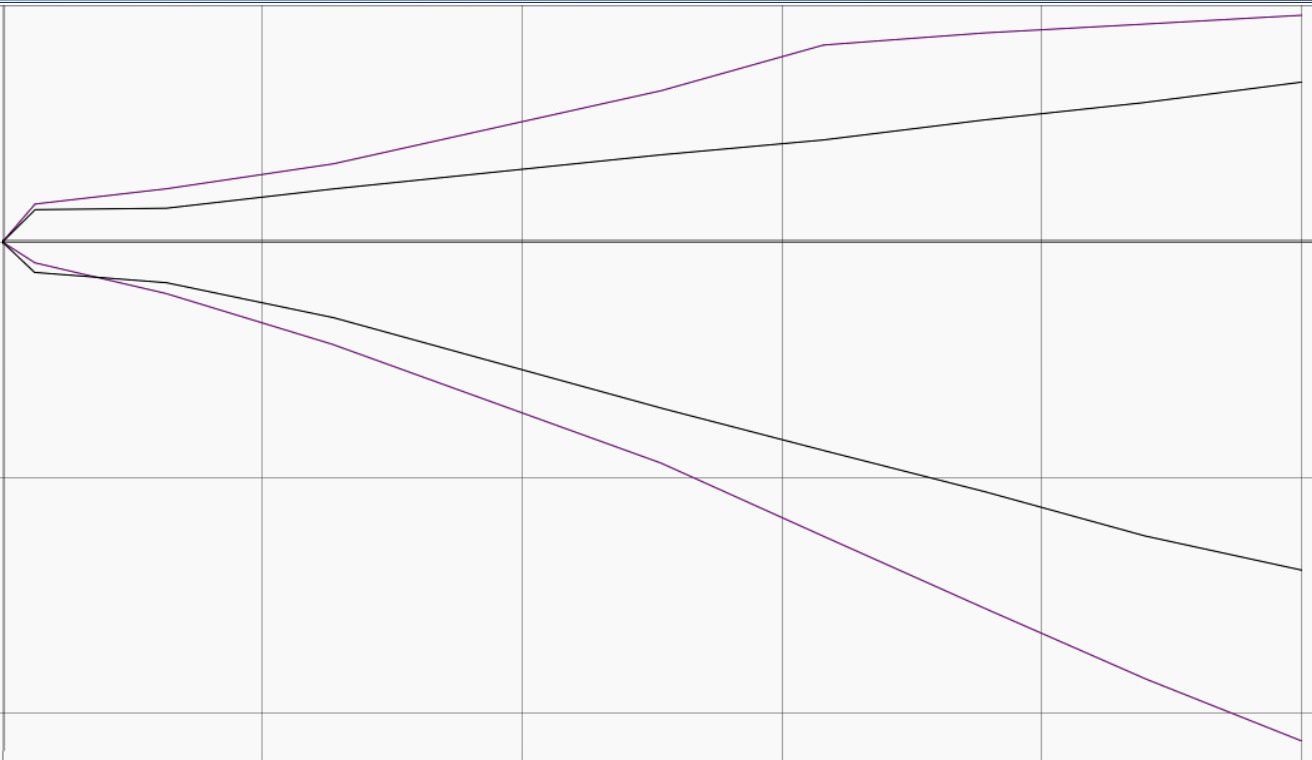

In addition, they prevent the shock from having a harsh bottom out. The tapered design will help ease into the ending stroke of the shock, so the rider doesn’t feel like they are “hitting a wall.”

Having multiple rate bump stops will help suspension tuners, like Fluid Focus, fine tune their customers’ suspension. Additionally, frame manufacturers then have options on the kinematics of the frame design, as well as the stroke of the shock when ordering their desired shocks from the suspension manufacturer.

Furthermore, the shock manufacturers will have potential alternative options to offer frame manufacturers.

Traditionally, bump stops have been used on coil shocks. One advantage to using these bump stops in air shocks, is that since they are taking up volume within the shock’s air can, Fluid Focus has been able to reduce and/or remove some of the volume spacers that riders have been relying on for so long. Also, in shocks with smaller strokes (40-55mm), these bump stops will give heavier riders more support through the shocks’ entire range.

Design Features

Tapered designs

Oil & grease resistant

100% Made in the USA

Superior rider protection

Support for heavier riders

35 & 45 durometer options

Built for air and coil shocks

Customized designs available

4 standard bump stop cavity sizes

High-performance polyurethane (PU)

Support of all major mountain bike shock brands and OEMs

Advantages & Benefits of Using Bump Stops in Air & Coil Shocks

There are several advantages and benefits of using bump stops in mountain bike suspension systems, whether air or coil shocks. In the past, bump stops have been used on coil shocks. However, one advantage to using them in air shocks is due to the fact they are taking up volume within the shock’s air can, we’ve seen suspension tuners, such as Fluid Focus, be able to reduce and/or remove some of the volume spacers that riders have been reliant on.

Additionally, for shocks with smaller strokes (i.e. 40-55mm), bump stops give heavier mountain bike riders more support through the entire range of the shocks. By having multiple rate bump stops, suspension tuners are able to fine tune customer’s suspensions better. Also, frame manufacturers have more options based on the kinematics of the frame design, and the stroke of the shock, when ordering their desired shocks from the suspension manufacturer. Or, the shock manufacturers will have options to offer frame manufacturers.